Product Introduction

Automatic Wire Mesh Welding Machine Introduction

The Automatic Wire Mesh Welding Machine is a state-of-the-art equipment designed for efficient and precise welding of wire mesh. It is widely used in industries that require high-quality welded mesh products, such as construction, agriculture, and manufacturing.

Key Features and Benefits

Automatic Material Loading: This machine is equipped with an automatic material loading system, which eliminates the need for manual feeding. It reduces labor requirements and ensures a continuous production flow, increasing efficiency and productivity.

Flexible Mesh Size and Wire Diameter: The Automatic Wire Mesh Welding Machine supports a wide range of mesh sizes and wire diameters. It can produce both fine and coarse mesh patterns, catering to various application needs. The adjustment of mesh dimensions and wire spacing can be easily achieved through the control panel.

Precise Welding Control: With advanced welding technology, the machine offers precise control over welding parameters. It consistently delivers strong and reliable welds throughout the mesh, ensuring excellent structural integrity and longevity of the final product.

User-friendly Interface: The machine features a user-friendly interface that allows operators to easily program and control the welding process. It provides intuitive navigation and clear instructions, enabling quick setup and adjustment of welding parameters. Operators with minimal training can operate the machine smoothly.

High Production Efficiency: The Automatic Wire Mesh Welding Machine utilizes a high-speed welding process, resulting in improved production efficiency. It can produce a large number of welded mesh panels within a short period of time, meeting tight production deadlines and increasing output capacity.

Robust Construction and Longevity: This welding machine is built with high-quality materials and components, ensuring durability and long-term reliability. It can withstand continuous operation and heavy workloads, requiring minimal maintenance and reducing downtime.

Safety Features: The Automatic Wire Mesh Welding Machine is equipped with various safety features to protect operators and ensure safe operation. These features include emergency stop buttons, safety guards, and light curtains, which effectively prevent accidents and injuries.

Customization Options: The machine can be customized to meet specific requirements and preferences. Additional features, such as automatic mesh cutting and stacking, can be incorporated to further streamline production and improve workflow efficiency.

Product Summary

In summary, the Automatic Wire Mesh Welding Machine is a versatile and efficient solution for wire mesh welding. Its automatic material loading system, precise welding control, and user-friendly interface make it an ideal choice for businesses seeking productivity enhancement and superior welded mesh quality. Consider incorporating this machine into your production line for optimized efficiency and cost-effectiveness.

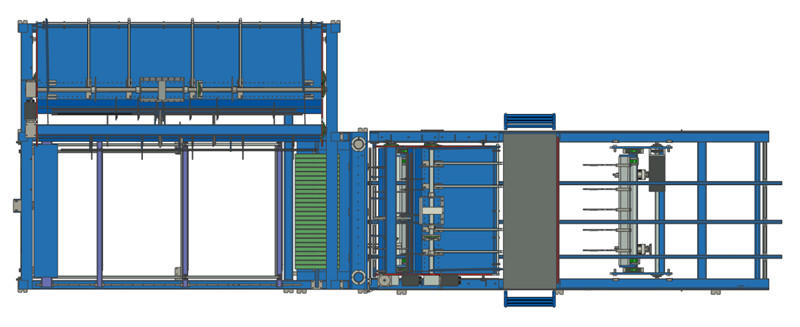

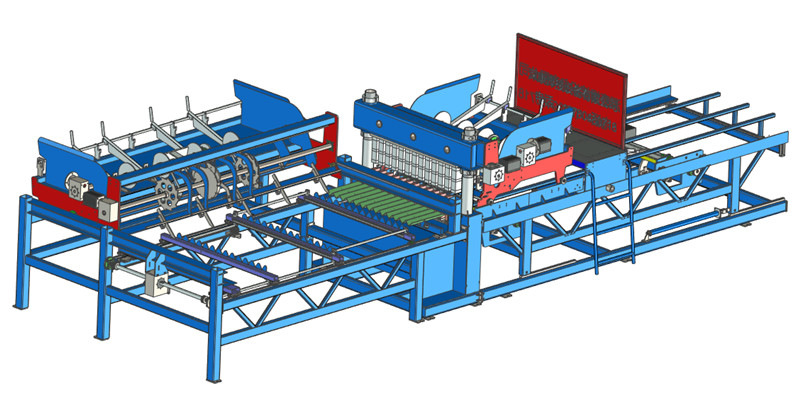

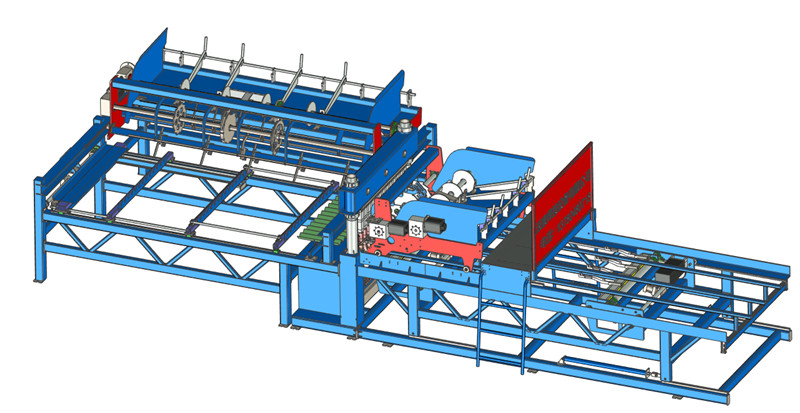

Wire Mesh Fence Welding Machine(pre-cut wire type)mesh width 2500mm, wire diameter 3mm-6mm or 4mm to 8mm, welding speed 60-80 strokes/min., line wire feeding form in pre-cut wire , cross wire feeding in pre-cut wire .

Standard configuration: auto placement of line wire, cross wire supplement hopper, main welding machine, servo motor mesh pulling , auto mesh output device, auto stacking , industry water cooling machine

Optional configuration: mesh output supporting roller, line wire supporting platform, stacking cart, air compressor, intermediate frequency welding system