Product Specification

| Model | GJW-X3300 | GJW-X2500 |

| Mesh width | ≤3300mm | ≤2500mm |

| Wire diameter | 6mm-12mm | 6mm-12mm |

| Cross wire space | ≥50mm | ≥50mm |

| Welding electrode No. | 32 | 24 |

| Cross wire type | ≥1000mm, Pre-cut wire | ≥1000mm,Pre-cut wire |

| Line wire type | Pre-cut wire | Pre-cut wire |

| Welding speed | 45-75 strokes/min. | 45-75 strokes/min. |

| Welding transformer | 180KVAX16 | 180KVAX12 |

| Diagonal error | ±5mm( mesh sheet of 2m length) | ±5mm( mesh sheet of 2m length) |

| Material | Smooth or ribbed wire (cold rolled) | Smooth or ribbed wire (cold rolled) |

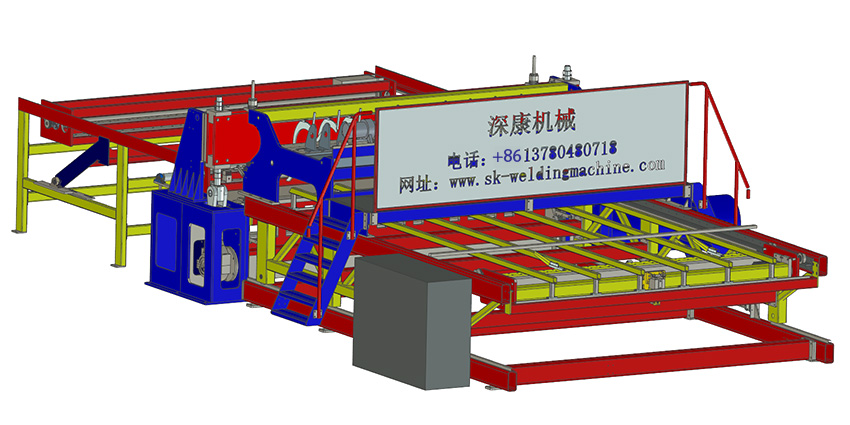

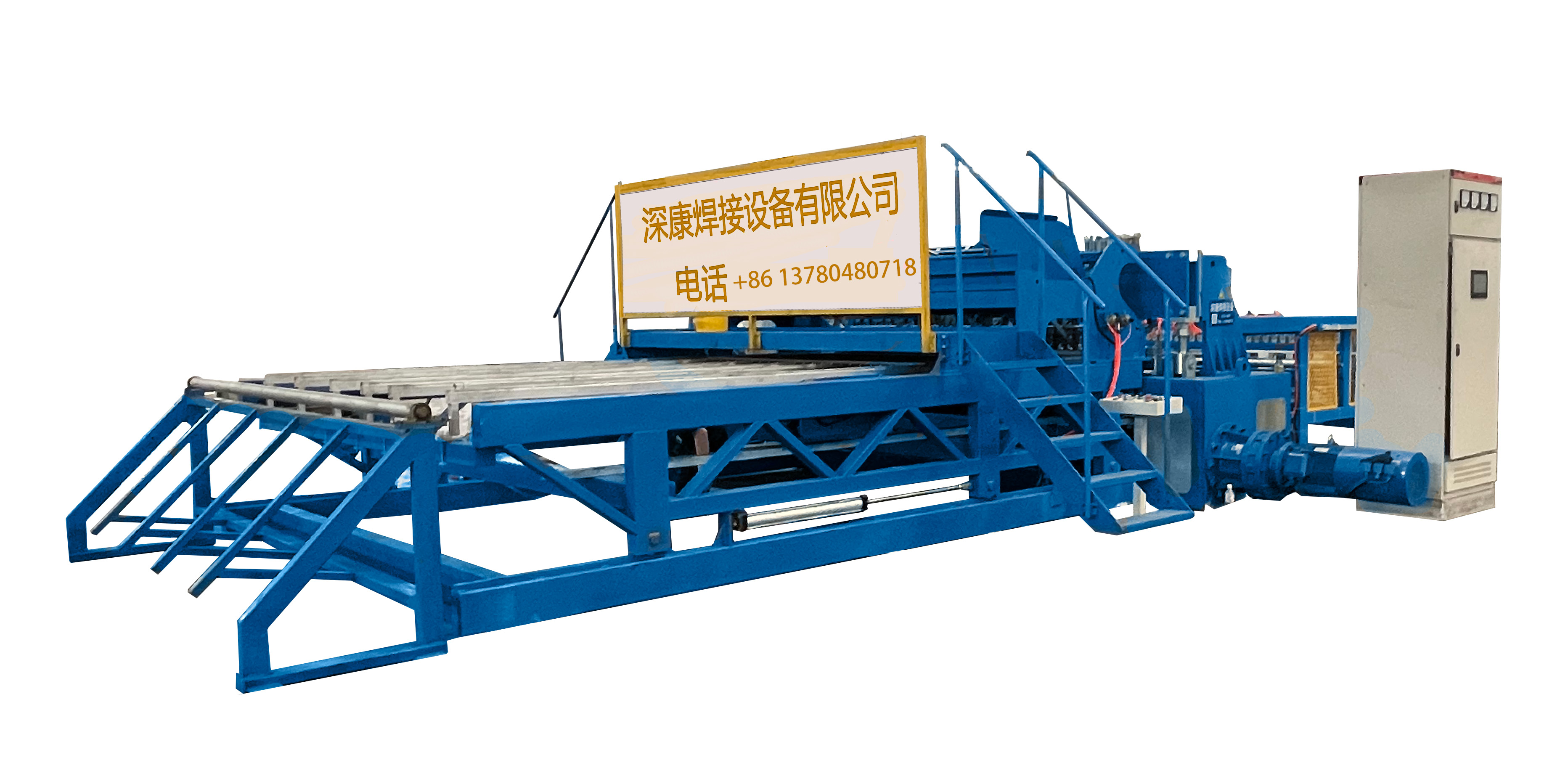

Steel mesh welding production line, the width of the welded mesh is 3300mm, the diameterf the welding wire is 6-12mm, the welding speed is 45-70 times/min, and the vertical andhorizontal lines are all broken.

Standard configuration: Longitudinal line feeding rack, feeding trolley, welding host,increasing material hopper, servo pulling net.

Optional equipment: automatic landing and netting trolley, automatic net turning and nettincchiller; air compressor.

Product Introduction

The steel mesh welding machine is a professional automatic equipment for welding steel mesh. It is mainly composed of welding system, control system and conveying system.

The welding system uses resistance welding techniques to join the rebar to the electrodes through electrodes. Welding systems typically include a torch or tongs to bring the electrode into contact with the rebar. By delivering electric current and applying pressure, the welding system is able to securely weld the electrode to the rebar.

The control system is the brain of the welding machine, responsible for controlling welding parameters, operation mode and speed, etc. Generally, the control system is equipped with a touch screen or human machine interface so that the operator can easily adjust and monitor the welding process.

Conveyor systems are used to convey and position rebar and welding rods. It usually consists of a conveyor belt or drum that transports the rebar and welding rods from the feeding area to the welding area and ensures that they are arranged in a predetermined pattern.

Product Applications

The steel mesh welding machine has efficient, precise and stable welding capabilities. It can automatically complete the welding task of steel mesh, improve production efficiency, and reduce labor costs. The equipment is widely used in construction, bridges, tunnels and other steel bar processing fields.

Product Tips

It should be noted that different models and brands of steel mesh welding machines may have different functions and specifications. Before purchasing, it is recommended that you learn more about the characteristics of different devices, and choose the appropriate model and specification according to your actual needs.