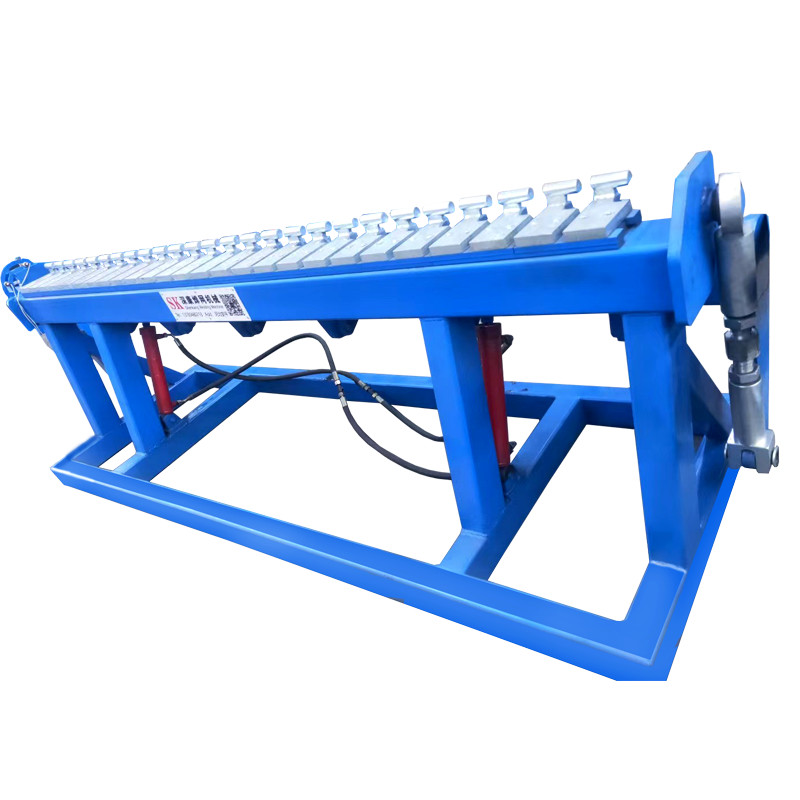

Product Specification

| Max. Wire diameter | 6mm |

| Max. mesh width | 3000mm |

| Max. bending angle | 120 degree |

| Bending type | Hydraulic |

| Max. bending force | 61 pieces of wires when wire diameter 6mm |

| Min. wire space | 50mm |

| Power supply | 380V/3P/50Hz |

| Total power | 7.5KW |

| Overall dimension | 3.2x1.2x1.0m |

| Weight | `1300kgs |

Operation system:SHENKANG

Dynamic system: original

Classification: auxiliary machines

Product summary: P type mesh bending machine, max. bending wire diameter 6mm, bending mesh width 3000mm, max. bending angle 120 degree, max. bending force is 61 pcs of wires (wire diameter 6mm)

Company address: No. 17, Canda Chuangye Base, Anping County,, Hebei Provice

Equipment Features

The guardrail mesh bending machine adopts advanced numerical control technology and automatic control system, and has the following characteristics:

High precision: The equipment is equipped with precise guide rails, sensors and driving devices, which can realize high-precision bending processing and ensure the dimensional consistency of each fence mesh.

High efficiency: the use of automatic operation and quick mold change system can greatly improve production efficiency and reduce manual operation time.

Stability: The frame structure of the equipment is firm and stable, and the bending process is smooth and error-free, ensuring the stable quality of the guardrail mesh.

Easy to operate: Equipped with an intuitive and easy-to-understand operation interface, users only need to simply set parameters to easily realize mass production.

Safe and reliable: The equipment is equipped with multiple safety protection devices to ensure the safety of operators and avoid accidents.

Working principle: The guardrail mesh bending machine adopts the numerical control system to control the movement of the pressing piston and the bending die to realize the bending process of the metal sheet. Specific steps are as follows:

The operator inputs the required bending size and angle through the equipment control interface.

The sheet metal is placed on the bench, fixed in place and clamped for stability.

According to the set parameters, the control system directs the pressing piston to press down according to the prescribed speed and strength, so that the metal plate is bent on the bending die.

After one bending is completed, the workbench will automatically adjust, enter the next bending position, and perform the bending operation again.

Repeat the above steps until all the bending processes are completed to obtain a complete guardrail mesh product.

Scope of application:

The fence mesh bending machine is widely used in the manufacture of fence mesh in roads, railways, bridges, airports and other places. It can process various types of metal sheets, such as steel plates, stainless steel plates, etc., and can realize various bending forms and complex guardrail mesh designs.

Technical Parameters

Maximum bending length: can be customized according to user needs, usually ranging from 2 meters to 6 meters.

Maximum bending thickness: generally ranging from 2mm to 6mm, but can also be customized according to user requirements.

Numerical control system: Adopting advanced numerical control system, it can realize high-precision bending processing.

Power and energy consumption: The specific power and energy consumption depends on the device model and specifications.