Product Specification

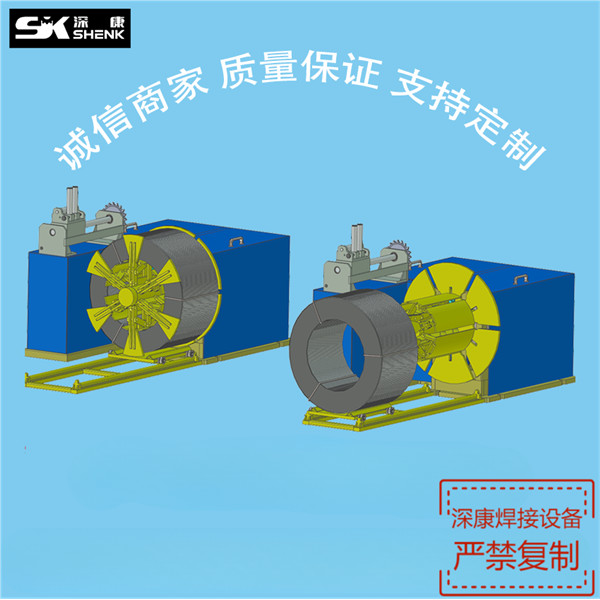

Automatic Hydraulic take-up machine (side opening type)

Hydraulic side-opening take-up machine is a kind of metal wire take-up device with automatic unloading the metal wire coils. With hydraulic control, it can automatically shrink, open and close, significantly improving production efficiency and reducing labor intensity. It is a replacement product of the ordinary steel wire take-up machine. Shenkang Machinery can customize the size of the I-shaped wheel according to customer needs to achieve Φ 3-12mm, 500kg - 1200kg wire winding ofΦ 3-12mm, 500kg - 1200kg wire coils.

Product details:

1. Variable frequency speed regulation - variable frequency control cabinet, one key operation, saving labor.

2. Support customization - do a good job of products to meet the different needs of customers.

3. Excellent material selection - to benefit customers and save costs for customers

Company address: No. 17, Canda Chuangye Base, Anping County,, Hebei Provice

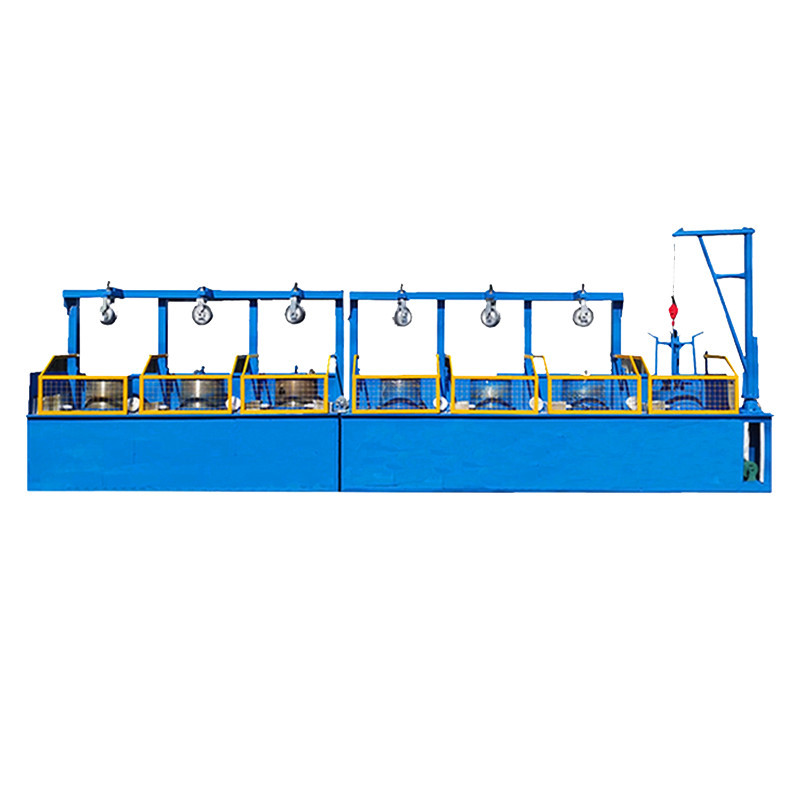

Hydraulic Side Opening Mesh Stacking Machine

The hydraulic side opening mesh stacking machine is a specialized equipment designed for efficiently stacking wire mesh panels. It is widely used in industries that involve the production and handling of wire mesh, such as construction, manufacturing, and fencing.

Key features and advantages

Versatile and adjustable: The machine is versatile and adjustable, allowing it to handle different sizes and shapes of wire mesh panels. It can be easily programmed to accommodate various stacking patterns and configurations, providing flexibility for different production requirements.

Automated operation: The hydraulic side opening mesh stacking machine is equipped with automated features, such as conveyor systems and hydraulic arms, which eliminate the need for manual stacking. This reduces labor costs and increases overall efficiency by streamlining the stacking process.

Precise stacking: With its hydraulic system, the machine ensures precise stacking of wire mesh panels, maintaining uniformity and reducing the risk of damage during handling and transportation. This enables a higher level of quality control and minimizes product wastage.

High productivity: The machine is designed for high productivity and can handle a large volume of wire mesh panels in a short period of time. This increases production rates, reduces lead times, and improves overall operational efficiency.

Space optimization: The hydraulic side opening mesh stacking machine is designed to optimize space utilization. It effectively stacks the panels in compact configurations, saving valuable floor space in warehouses and production facilities.

Safety features: Safety is a priority, and the machine is equipped with safety features to ensure the well-being of operators and prevent accidents. Emergency stop buttons, safety sensors, and guards are incorporated to provide a safe working environment.

Durability and reliability: The machine is constructed with high-quality materials and components to ensure durability and reliability. It is designed to withstand heavy-duty and continuous operation, minimizing downtime and maintenance requirements.

Product Summary

In conclusion, the hydraulic side opening mesh stacking machine is an essential tool for businesses involved in wire mesh production. Its versatility, automated operation, precise stacking, high productivity, space optimization, safety features, and durability make it an efficient and reliable solution for optimizing production efficiency and reducing costs. By utilizing this machine, businesses can increase output, improve product quality, and streamline their operations.

It is a replacement product of the ordinary steel wire take-up machine. Shenkang Machinery can customize the size of the I-shaped wheel according to customer needs to achieve Φ 3-12mm, 500kg - 1200kg wire winding ofΦ 3-12mm, 500kg - 1200kg wire coils.

Product details:

1. Variable frequency speed regulation - variable frequency control cabinet, one key operation, saving labor.

2. Support customization - do a good job of products to meet the different needs of customers.

3. Excellent material selection - to benefit customers and save costs for customers