Product Introduction

Cyclic Mesh Welding Machine Introduction

The Cyclic Mesh Welding Machine is an advanced and efficient solution for welding wire mesh. It is specifically designed for various applications that require strong and durable welded mesh, such as fence panels, construction reinforcement, and industrial manufacturing.

Key Features and Benefits

High Welding Efficiency: The Cyclic Mesh Welding Machine features a cyclic welding process that significantly improves efficiency. It can continuously produce welded mesh panels with high precision and speed, reducing production time and increasing productivity.

Versatility in Mesh Sizes and Wire Diameter: This welding machine is capable of welding different mesh sizes and wire diameters, making it suitable for a wide range of applications. From small and intricate mesh patterns to large and heavy-duty panels, the machine can easily handle various requirements.

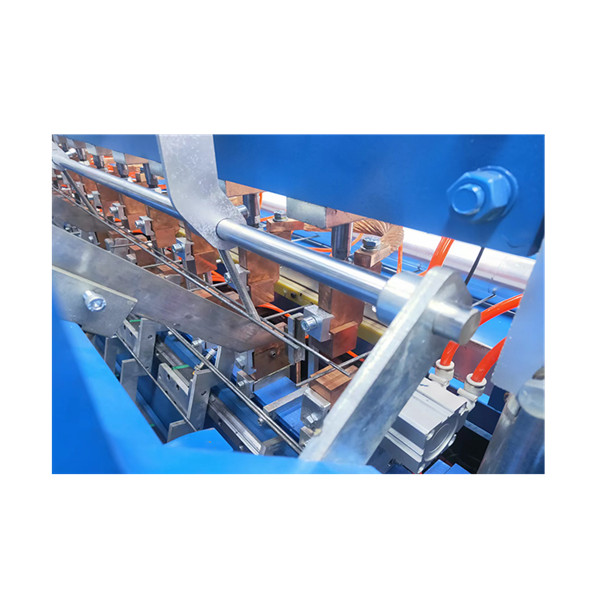

Precise Welding Control: Equipped with advanced welding technology, the machine ensures precise control over welding parameters. This results in consistent and strong welds throughout the entire mesh, providing excellent structural integrity and longevity.

User-friendly Operation: The Cyclic Mesh Welding Machine comes with an intuitive interface that allows for easy operation and adjustment of settings. Operators can quickly set the desired mesh dimensions, wire spacing, and welding parameters, streamlining the production process.

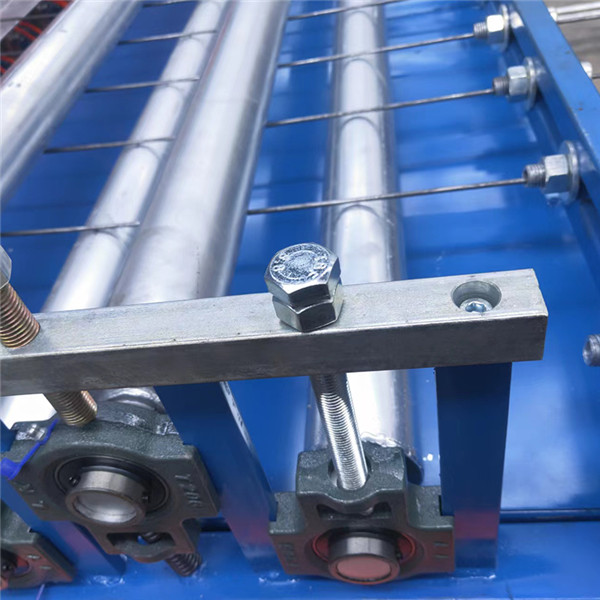

Durability and Reliability: Built with high-quality materials and components, this welding machine is designed to withstand continuous operation and heavy-duty usage. It offers long-term reliability and requires minimal maintenance, reducing downtime and maximizing production efficiency.

Customization Options: The Cyclic Mesh Welding Machine can be customized to meet specific requirements and preferences. Additional features, such as automated mesh stacking, cutting, and wire straightening options, can be incorporated to further enhance productivity and convenience.

Cost-effectiveness: By automating the welding process, the machine reduces labor costs and minimizes material waste. This makes it a cost-effective solution for businesses while maintaining high-quality welded mesh output.

Product Summary

In conclusion, the Cyclic Mesh Welding Machine is a versatile and efficient solution for various welding applications. With its high welding efficiency, precise control, and durability, it meets the demands of different industries and provides reliable results. Consider using this machine for your wire mesh welding needs to improve productivity and achieve superior weld quality.

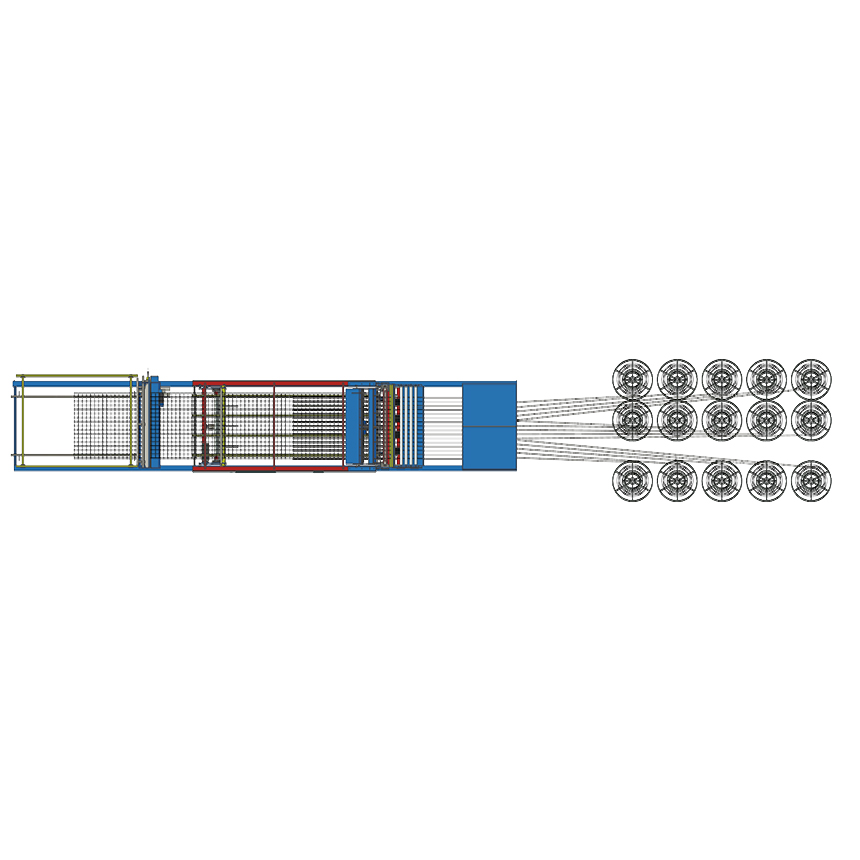

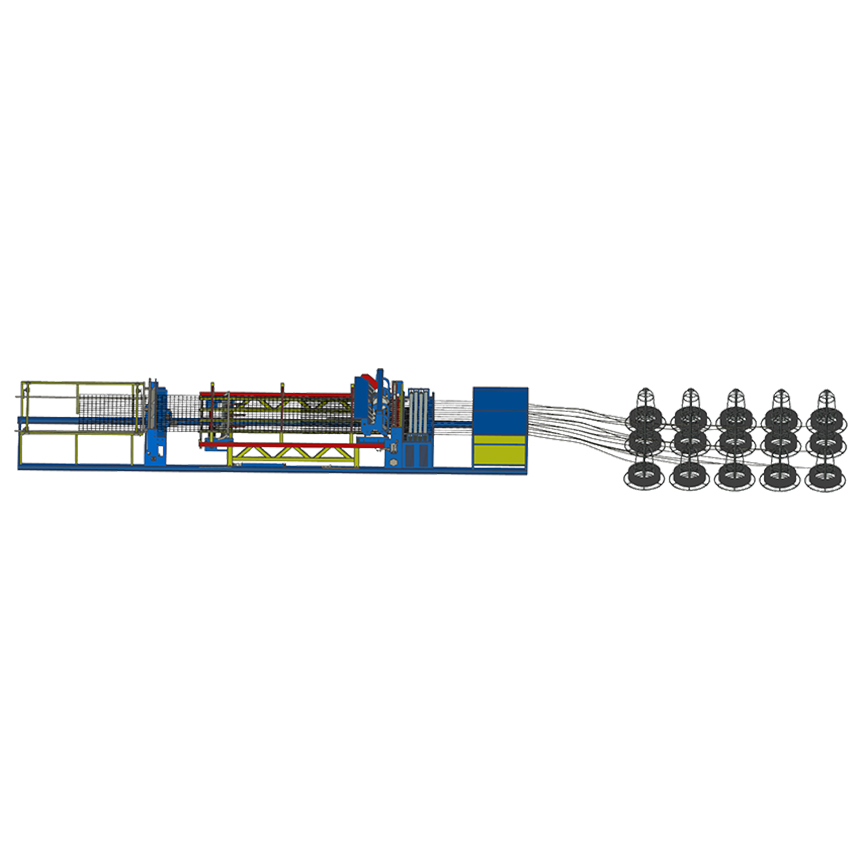

Automatic fence Mesh welding machine(loop Pull the net)mesh width≤1200mm/1600mm,2100mm,2500mm, wire diameter: 3mm-6mm or 4mm to 8mm, welding speed: 60-80 strokes/min., line wire feeding in coil wire, cross wire feeding in pre-cut wire.

Standard configuration: wire payoff stand, line wire pressure roll, main welding machine, cross wire hopper, mesh pulling device.

Optional configuration: line wire straightening roller assembly, mesh cutting machine, automatic mesh unloading device( mesh output device)